Are you weighing up whether installing sheet metal roofing is the right move? You’re not alone—many homeowners wonder if the benefits outweigh the upfront costs. Metal roofs can tackle intense heat, hail, and storms without batting an eye, but they’re only as good as their installation. If you skip critical steps, you’ll face leaks, rust, and expensive fixes. This article provides a comprehensive guide to installing sheet metal roofing with confidence. From essential checks and safety measures to maintenance tips and energy efficiency gains, you’ll find straight answers—no fluff or jargon.

What should you check before installing a sheet metal roofing system?

Before diving in, double-check everything. A few simple checks can prevent headaches down the track.

- Structure Assessment: Verify the frame can handle the load of the sheets, especially in regions prone to storms. Strong framing keeps panels secure during high winds and prevents long-term sagging. This is especially vital for larger roof spans that carry heavier loads.

- Substrate Inspection: Look for sagging rafters or moisture damage that could compromise the structural support. Even slight warping can create gaps that cause leaks or misalignment of the panels. Timber rot often hides beneath old coverings and only becomes visible once the sheets are removed.

- Measurement Review: Accurate measurements stop alignment issues that lead to leaks. Always measure ridge lines, eaves, and valleys twice to confirm uniformity, and don’t rely on previous plans alone. Double-checking every dimension saves costly rework in the future.

- Approval Confirmation: Ensure that all necessary permits and compliance documents are in order before commencing work. Councils may have regulations on colour choice, reflective coatings, and environmental considerations, which could limit some product selections.

When you’re confident, everything falls into place; installation is smoother and safer. Take the time to understand the complete metal roof installation guide, so you start on solid footing. Solid prep makes all the difference.

Why is professional installation important for sheet metal roofs?

Proper installation is critical for longevity. Skimping on skill leads to issues that can cost a fortune later.

- Precise Sealing: Technicians seal overlaps to prevent water from seeping in, thereby protecting the internal structure. Seals are also applied to fasteners to block moisture ingress, which helps avoid rust under washers and prevents premature corrosion.

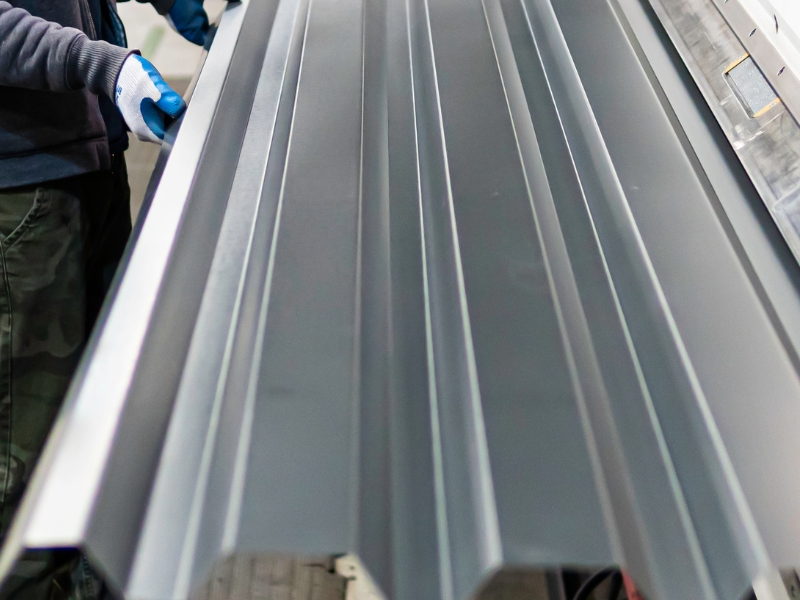

- Fastener Accuracy: Screws and clips are torqued to the correct specifications to prevent panel movement and ensure optimal performance.

- Weatherproof Flashing: Flashing is installed around penetrations to prevent moisture from entering the building. Chimneys, skylights, and vents are common problem areas that demand extra care to prevent water from pooling or seeping through.

- Time Efficiency: Professional teams work more efficiently, reducing exposure to adverse weather conditions during installation. Consistent progress prevents material warping from prolonged sun exposure or damp conditions that can distort sheets.

Relying on pros also means you can explore step-by-step installation tips for sheet metal roofing to see precisely what meticulous work looks like. Professional skill safeguards your investment.

Which safety measures are critical when installing sheet metal roofing?

Safety isn’t a box to tick—it’s a daily discipline. Height and sharp edges mean serious risks.

- Fall Prevention: Use harnesses and barriers to stop falls from elevated surfaces. Roof edges are particularly hazardous when wet or dusty, and strong gusts can unbalance even experienced workers without warning.

- Protective Gear: Gloves, helmets, and safety boots shield against cuts and impacts. Long sleeves and safety glasses prevent injury from sharp off-cuts and flying debris stirred up by wind.

- Weather Monitoring: High winds and rain can make metal sheets dangerous to handle. Always pause work when gusts exceed safe limits or when lightning is nearby. Unexpected weather changes can quickly create hazards.

- Clear Work Zones: Tools and materials are secured to avoid tripping or falling hazards. A tidy site also reduces confusion, improves workflow, and helps everyone stay focused on their tasks. Keeping walkways clear is a simple step that prevents accidents.

Many installers also consider exploring construction systems for sustainable roofing materials to see how safer practices align with eco-friendly materials. Stay alert to keep everyone safe.

How does installing sheet metal roofing impact long-term maintenance?

Installation quality shapes your maintenance workload. Done right, upkeep is minimal—done poorly, it’s relentless.

- Proper Fastening: Tight, secure fixings reduce the risk of loosening in storms. Loose screws can work free over time, leading to rattling panels and moisture seepage that damages insulation and timber.

- Adequate flashing stops leaks and keeps insulation dry year-round. Flashing in valleys and around penetrations is your first defence against hidden water damage and mould, which can spread quickly in damp conditions.

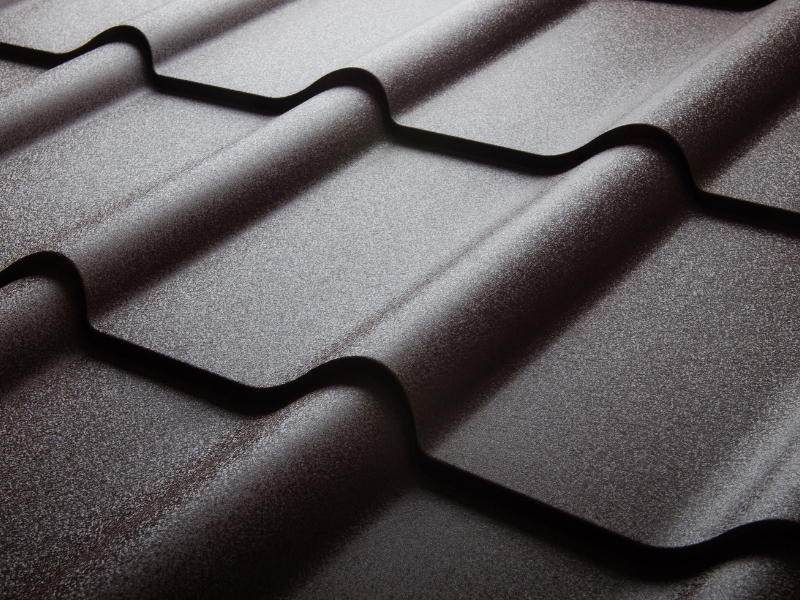

- Accurate Panel Overlaps: Prevents debris buildup that accelerates corrosion. Overlaps must be aligned and sealed to keep leaves, dust, and water out, which can quickly deteriorate protective coatings and shorten the lifespan of the roof.

- Ventilation Integration: Reduces condensation and mould growth in roof cavities. Good airflow also improves energy efficiency and keeps roof spaces cooler during the hottest months, reducing strain on insulation.

Here’s a quick look at how installation and material choices affect performance:

Material Type | Expected Lifespan | Maintenance Needs | Key Features |

Colourbond Steel | Up to 50 years | Occasional washing, inspections | Pre-painted finish, corrosion resistance |

Zincalume Steel | Around 45 years | Regular debris removal, checks | Aluminium-zinc coating for durability |

Galvanised Steel | 20–30 years | Frequent inspections, touch-ups | Cost-effective but prone to surface corrosion |

You’ll also see that the value of metal roofing for your home helps you weigh up initial effort against decades of low-maintenance benefits. Quality now means peace of mind later.

Can installing sheet metal roofing help improve energy efficiency?

Metal roofing isn’t just tough—it’s smart. Proper installation can lower energy bills while keeping your home comfortable.

- Reflective Finishes: Bounce sunlight off, reducing heat absorption. Lighter colours reflect more radiant energy, lowering attic temperatures significantly and easing the load on cooling systems.

- Insulated Layers: Limit heat transfer, keeping interiors cooler in summer. Adding insulation can also reduce outside noise from rain and wind, creating a more comfortable living environment.

- Airflow Design: Ventilation gaps help stabilise temperatures year-round. Ridge vents paired with eave vents are especially effective at moving warm air out and drawing in cooler air, thereby maintaining a consistent temperature.

- Sealed Joints: Prevent drafts and improve overall thermal efficiency. Tight seals also prevent insects, dust, and debris from entering around edges and gaps, which helps protect insulation from contamination.

Energy savings start with smart installation.

Final thoughts

Metal roofing isn’t a set-and-forget project. From preparation to finishing touches, every detail matters. Take time to inspect, measure, and plan so the results last decades. This article has walked you through the major factors—structural checks, safety protocols, professional practices, and energy considerations. For extra guidance on how each phase ties together, you might find it helpful to learn how Scott’s Metal Roofing ensures a smooth process that simplifies complex decisions. Start strong to finish strong—your roof depends on it.