Installing a metal roof might seem straightforward, but the difference between a job done right and one done poorly can be massive. Long before problems become visible, flaws in installation can compromise durability, safety, and overall performance. Whether you’re building from scratch or replacing an old roof, understanding the stakes is key. Proper metal roof installation isn’t just about getting the panels in place—it’s about longevity, weather resistance, and structural integrity. This article explores why proper installation matters more than you might think.

Why do installation flaws often go unnoticed until it’s too late?

When metal roofs fail, the issue isn’t always immediately apparent. Minor errors in installation might not leak immediately, but can lead to big trouble down the track.

- Minor gaps between panels can invite wind-driven rain

- Incorrect fastener placement weakens structural resistance

- Poorly sealed flashing lets water seep into the framing

- Inconsistent panel alignment increases wear from thermal movement

These subtle flaws often remain hidden until severe weather or seasonal changes expose the weak spots. Homeowners only discover the damage when watermarks appear, insulation sags, or pest activity spikes. By then, you’re no longer dealing with a minor patch-up.

That’s why it’s worth taking time to discover reliable ways to ensure high-quality metal roof installation, especially if you’re planning a new build or replacing an older roof.

What problems can occur without proper metal roof installation?

Skipping critical steps during installation sets up a domino effect of issues. Water, wind, and structural stress all target the weak links.

- Leaks develop around misaligned seams and under-tightened screws

- Roof noise increases with unsecured or warped panels

- Rust and corrosion form where coatings are scratched or exposed

- Insulation performance drops due to air gaps or moisture intrusion

These aren’t minor inconveniences—they can cut a roof’s life short by years. Over time, structural supports may also weaken from water penetration, leading to high-cost repairs. For example, you can better understand the impact by learning how a recurring leak affects the longevity of a metal roof, especially in coastal or storm-prone areas.

Delaying maintenance only makes things worse, increasing labour and material costs. Preventing these problems starts at install, not after something goes wrong.

How can poor metal roof installation lead to long-term damage?

It’s tempting to assume any roof with panels screwed down is “good enough.” But improper techniques cause cumulative damage, turning minor flaws into full-blown issues over time.

- Trapped moisture leads to timber rot in battens and trusses

- Thermal expansion stresses weak joints and warped panels

- Compromised insulation creates condensation and mould growth

- Excessive roof movement stresses flashings and ridge caps

These issues don’t show up overnight. Instead, they quietly degrade the roof’s structure until urgent repairs are needed. Worse still, neglecting early warning signs can double your replacement costs, especially when water reaches electrical or plasterboard systems.

Rather than gambling on patch-ups, it’s smarter to understand the benefits of following a detailed metal roof installation guide from the start. Consistency during installation protects every layer beneath the surface, not just what you see from the street.

What steps ensure proper metal roof installation?

A proper install isn’t just about skill—it’s about precision, patience, and step-by-step procedures followed to the letter.

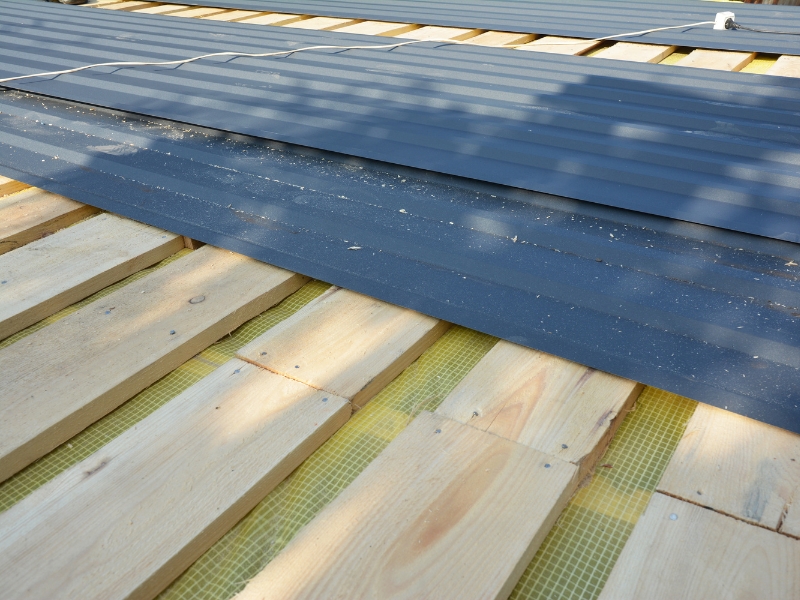

- Prep surfaces by removing old nails, smoothing battens, and checking pitch

- Lay underlayment with an overlap to prevent water ingress

- Align panels accurately before fixing to avoid “creep” along rows

- Use manufacturer-approved fasteners at specified intervals

- Seal all flashings, ridge caps, and penetrations completely

No two roofs are identical, so the principle of measuring twice and cutting once still applies. Even seasoned pros double-check specs. Training, tools, and teamwork make the difference, especially on steep slopes or multi-level structures.

Here’s a simplified table that shows key steps and their consequences when skipped:

Step Missed | Common Outcome |

No underlayment | Moisture intrusion, reduced R-value |

Misaligned panels | Uneven load, thermal stress |

Wrong fasteners or spacing | Loose panels, increased wind damage |

Poor sealing around flashings | Hidden leaks, wall damage |

Does proper metal roof installation prevent costly repairs?

Absolutely. Getting it right the first time significantly reduces the need for future work. When the roof performs as designed, fewer callouts, replacements, and internal repairs are needed.

- Tight seals and correct pitch stop wind-driven rain

- Even spacing of fixings prevents buckling or rattling

- Thermal movement is managed, not fought

- Flashings stay sealed under pressure

In contrast, poor installation leads to reactive repairs, often requiring multiple repairs. Leak detection alone can be time-consuming and expensive. Materials may be covered under warranty, but labour is rarely covered.

By building it right from the start, you can avoid emergency repairs and preserve your investment. Safe techniques also matter. Many homeowners aren’t aware of the best practices for staying safe while working on roofs, which are essential when evaluating both DIY and contractor work.

What are the dangers of installing a metal roof on your own?

DIY installation may seem like a way to save money, but it introduces significant risks. Beyond the physical danger, even small mistakes can void warranties and reduce long-term performance.

- Incorrect screw placement leads to uplift in strong winds

- Cutting panels with the wrong tools exposes them to rust

- Underestimating fall risk, especially on wet or steep surfaces

- Failure to seal flashings causes hidden water damage

Short-term savings often lead to long-term loss. If a fall doesn’t injure you, the cost of fixing incorrect work can still burn a hole in your wallet. There’s also the issue of compliance—local codes often require qualified installers for insurance to apply.

In many cases, homeowners only realise the danger after a small job becomes a big mess. That’s why, even if you’re handy, complex roofing is best left to professionals who follow safe and effective installation methods.

How does correct installation affect roof durability over time?

The longevity of a metal roof depends more on installation than material. Premium panels won’t perform if they’re poorly installed.

- Proper alignment prevents “oil canning” and stress fractures

- Secure flashing resists storm damage

- Well-fastened panels reduce wind uplift and vibration

- Sealed seams block corrosion-causing moisture

Correct installation supports every performance promise. When installed correctly, a metal roof can last over 40 years with minimal maintenance. It will also maintain its appearance, resist pests, and reduce energy costs by reflecting more heat.

Neglecting installation standards can significantly shorten the lifespan, especially in areas with heavy rainfall or high UV exposure. That’s why planning, execution, and inspection are all critical stages—not just final clean-up.

Final thoughts

A metal roof is a wise investment, but only if installed correctly. Every detail, from screw depth to seam alignment, affects how the roof performs and its longevity. Skipping steps, rushing the job, or relying on assumptions opens the door to leaks, noise, rust, and costly repairs. Correct installation isn’t just about avoiding problems—it’s about delivering the full value of a metal roof for decades to come. If you’re looking for experienced support, discover how Scott’s Metal Roofing can support your metal roofing needs.